Mecalab designed and integrated a 1.5 m³ 316L stainless steel process tank with under-tank pump, dedicated to food industry applications requiring hygiene, precision and industrial quality.

Pure water & air

technologies

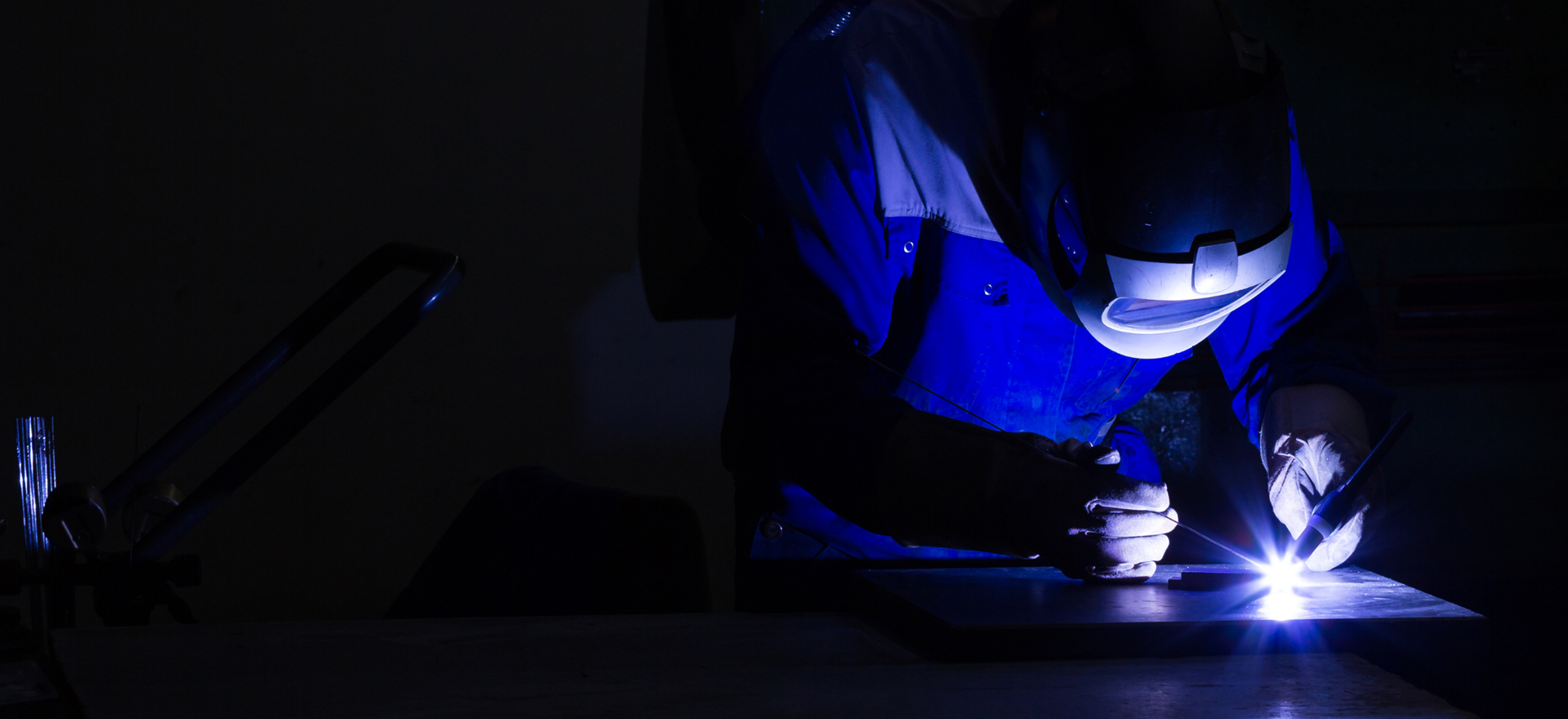

Mecalab designs high-precision piping networks and mechanically welded components, ensuring strict standards of hygiene and traceability for the cosmetic & life sciences, food, and industrial sectors.

News

Mecalab designed and integrated a 1.5 m³ 316L stainless steel process tank with under-tank pump, dedicated to food industry applications requiring hygiene, precision and industrial quality.

Mecalab has been ISO 9001 certified since December 2025, ensuring reliable services that meet international standards in engineering, piping, and mechanical welding.

Project to connect stainless steel black piping to evaporators in a data center, including craning, prefabrication and reuse of parts of the existing circuit.

Find out how Mecalab uses penetrant testing and radiography for non-destructive testing of welds.

Mecalab designed and manufactured the 316L stainless steel casing integrating two 3D-printed static mixers, intended for testing at a customer's facility in the chemical sector.

A tailor-made solution for liquid paste transport

Have questions or a project to discuss? Our team is here to provide information and assist you with your piping and mechanical welding needs. Fill out our contact form, and we will get back to you as soon as possible. We look forward to working with you!